Reactor is a kind of atmospheric pressure or pressure vessel that is applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries, and used to complete the process of vulcanization, nitration,hydrogenation, alkylation, polymerization, condensation, also called polymerization reaction kettle, reactor, decomposition kettle, etc.

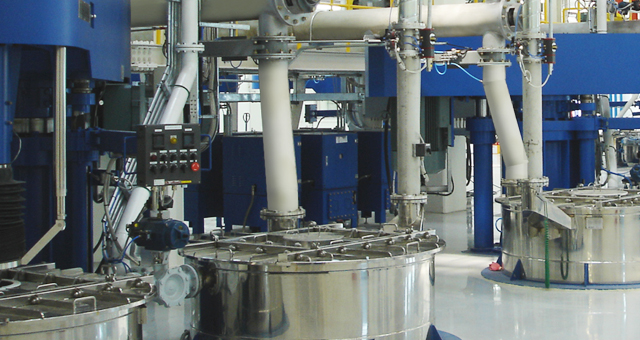

Mixing kettle, which is used for liquid-liquid or powder-liquid blending and mixing, is a type of large-scale production equipment and has the functions of dispersing, emulsifying, heating and cooling, to fulfill different production process requirement; It can be stably running for long time, has the advantages of small noise, simple operation and strong adaptability, is the ideal multi-functional equipment for mixing and dispersing.

Atmospheric pressure vessel, is a kind of vessel shares same pressure as atmosphere, applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries, and used to complete the process of storage, temporary storage or non-pressure mixing. This type of machine is usually equipped with breathing valve or vent.

Pressure vessel, is a kind of vessel that carries certain pressure, applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries, and used to complete the process of storage, temporary storage or mixing. This type of machine is special technical equipment.

Vertical storage tank, is a kind of storage container applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries. Vertical storage tank includes atmospheric pressure storage tank and pressure storage tank. The equipment material usually adopts carbon manganese steel, stainless steel, zirconium, nickel based (Harrington, Meng Naier, Kang Nie) alloy and other composite materials. Siehe Industry mainly produces the stainless steel or carbon manganese steel model.

Horizontal storage tank, is a kind of storage container applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries. Horizontal storage tank includes atmospheric pressure storage tank and pressure storage tank. The equipment material usually adopts carbon manganese steel, stainless steel, zirconium, nickel based (Harrington, Meng Naier, Kang Nie) alloy and other composite materials. Siehe Industry mainly produces the stainless steel or carbon manganese steel model.

Intermediate tank, is a kind of temporary storage container applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries. Intermediate tank can be also used for liquid and powder dispatching process, such as layering, solvents and water separation, purification, etc. The equipment material usually adopts carbon manganese steel, stainless steel, zirconium, nickel based (Harrington, Meng Naier, Kang Nie) alloy and other composite materials. Siehe Industry mainly produces the stainless steel or carbon manganese steel model.

Sanitary vessel, includes storage vessel, tank and mixing tank, etc.,is mainly applicable for industries like: biological, pharmaceutical, food, beer & beverage, dairy product, fine chemicals, cosmetics, etc., entirely designed and manufactured in accordance with SMP standard. The part contacting materials is mirror polished to Ra≤0.28um, and surface is polished, mirror polished, sandblasting or matte treated. Level meter port, air respirator, thermometer, CIP cleaning port, SIP sterilization port, sight glass(integrated with a lamp), inlet and outlet and manhole etc.are optional.

Movable tank, referred to as tank, is mainly used for small scale production mixing or storing. The tank adopts high-quality stainless steel, argon-arc welding whose seam has been nicely treated; mirror polished inside and outside, easy to clean; also, the tank bottom is with inclination angle ensures clean discharging and no residue。

In the actual production, the factors such as materials feature, production process, operation requirement and volume etc. varies a lot, so besides the normal standard vessels, Siehe also do non-standard vessels’ customizing. The customized vessels can be combined with dispersing, grinding, emulsifying, heating, cooling and vacuum function, to fulfill the needs of different production process.