Small bag Feeding Stations is commonly used for unpacking and discharging for bags (25kg or 50kg) filled with powder or granule materials. The unpacking and discharging work is done through manual bag open, automatic dumping and let the materials fall down by gravity to the storage hopper. The dust generated during operation is collected by the build-in dust collection to ensure clear working environment for operators.

The Ton-bag discharging and feeding station is used for unpacking and discharging powder and granules in T-bag. This equipment consists of the rack, lifting device, diaphragm valve, temporary storage silo and so on; Two types: Use hoist and forklift according to production technology and equipment size. Dual track is optional for occasion of two electric hoist installation to increase the bag unpacking efficiency. The machine can be carbon steel or stainless steel. The whole machine is with good airtightness, easy to operate, which improve the working environment and also the production efficiency significantly.

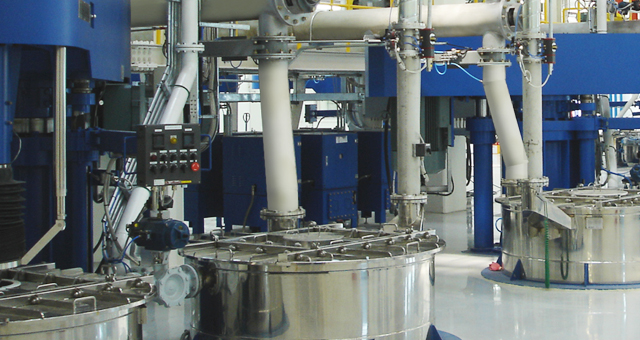

Discharging and Feeding Station for both small bag and ton bag is a new developed discharging and feeding system for not only ton bags but also small bags base on the ton bag discharging and feeding station, combined feeding to realize main material and auxiliary material discharged and fed at the same time. Dust removal and sieving function are in options. The machine can be carbon steel or stainless steel. The whole machine is with good airtightness, easy to operate, which improve the working environment and also the production efficiency significantly.

Small-bag Automatic Discharging Station is used for unpacking and discharging powder and granule materials in small bag. Automatically provide bags through belt conveyor, cutting device to break the bags automatically, vibrator to separate the bag and materials automatically, discharging materials etc.. Then the materials fall down to the storage hopper through gravity.