Semi-automatic Filling Machine(Weighing Type )adopts gravimetric method to measure, by weighing sensor output signal to control the charging valve opening, so as to realize the purpose of automatic filling. By equipped with a pump in the front end of the feeding port, or pressuring the material tanks to sent material from tank to the filling machine. The filter device can be added before filling to guarantee the quality of products.

Semi-automatic Filling Machine (Volume Type) adopts volumetric method to measure, through the way adjusting the plunger volume to realize the control of filling quantity. It is equipped with a pump in the front end of the feeding port, or pressuring the material tanks to send material from tank to the filling machine.

High Viscosity Semi-automatic Filling Machine adopts gravimetric method to measure, by screw extruder or high viscosity convey pump (such as screw pump, rotor pump) for feeding, conveying device with the function of frequency speed control can realize quick or slow feeding. Weighing sensor output signal control screw and the discharge of the pump (fast, slow, or stop feeding) to achieve automatic filling.

Big Drum Semi-automatic Filling Machine adopts gravimetric method to measure ,by weighing sensor output signal to control the charging valve opening, so as to realize the purpose of automatic filling. By equipped with a pump in the front end of the feeding port,or pressuring the material tanks to sent material from tank to the filling machine. The filter device can be added before filling to guarantee the quality of products.

Multi-heads Linear Automatic Liquid Filling Machine(Volume type) has the advantages of linear filling, which can apply to a variety of specifications of the bottles, convenient adjustment, free of maintenance and design, measurement methods using piston volume filling, continuous work, lasting stability, can match 2 to 12 filling head, and with the bottle convey ,position structure ,positioning ,screw cap cover device, whole machine PLC control, with detection device, no bottle no filling, no set or screw cap, filling with high efficiency, high filling precision, safety, and intelligent advantages.

Automatic Liquid Filling Machine (Volume Type) consists of the following parts: automatic arrangement of dividing barrel and lift barrel system, double head volume type filling system, convey system, automatic lift and gland cover system, automatic code/labeling system, the finished product output system, packaging platform, control system etc..

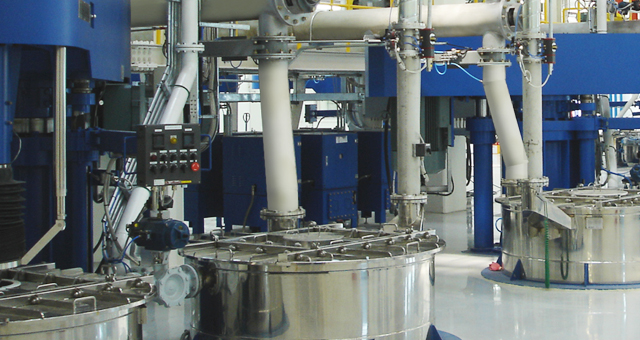

Automatic Liqui: filling Machine(Weighing Type) consists of the following parts:barrel lifting system, filling system, weighing system, block system, pallet supply system, pile tally system, electric appliance control, pneumatic control, vacuum system, rack, etc.. Under the electrical control, the machine finished the working of automatic bucket,quantitative filling,cover,detect,pallet, pre-stacking,stow and barrel pushed and automatic output. Automatic barrel lifting system: Filling machine is all automatic production from the barrel access part, only need to placed the same specifications and types of barrels neatly in the designated position,

Automatic Filling Machine (Big Drum) consists of automatic input and output track system, material automatic convey system, filter system, automatic canned metering system,the air and ground operation path, control system. Implements the process of send into barrels automatically- automatic peeling - automatic seek the barrel mouth -automatic fall down - fast canned - slow accurate canned- automatically rise after canned - seek barrels mouth repeatedly - four barrel canned end - automatic send barrels out - new bucket automatically to the filling position.

Automatic Filling and Sealing Machine control part adopts the most advanced intelligent man-machine interface control, large screen touch screen display/control panel operation, including temperature setting, motor speed, production speed and so on, directly display on the screen, and can be directly control and adjust on the screen.

Small Batch Paste&Filling Machine(Volume Type )adopt volumetric method to measure,through the way adjust the plunger volume to realize the control of filling quantity.The reciprocating movement of the piston achieves filling rapidly.The equipment has advantages of high filling efficiency and easy maintenance.

The progress of modern science and technology make all walks of life are gradually entering into the automatic intelligent generation. SIEHE Industry has professional R&D team, who has continuous innovation, and has been developing sorts of new product keeping pace with the times. We have formed a series of product: Semi/Automatic Filling Machine (Volume Type), Semi/Automatic Filling Machine (Weighing Type), Semi/Automatic Filling Machine (Big Drum)