SIEHE water-based production equipment ranges from single equipment with 500T/year capacity to complete production line with 100,000 ton/year capacity. We have successfully serviced customers specialized in water-based paint, water dilutable coating, water dispersible paint(latex paint), water soluble alkyd resin, water soluble epoxy resin, inorganic polymer water-based resin, etc.. Water-based paint complete production line adopts raw materials auto feeding system, metering system, basket dispersing and milling system, multi-function mixing and tinting system, cleaning system, auto control system, auto filling and etc advanced production methods.

SIEHE solvent-based production line ranges from single equipment with 500T/year capacity to complete production line with 100,000 ton/year capacity. We have successfully serviced customers from various of industries including nitro lacquer, polyurethane paint, enamel, varnish, anti-corrosion paint, finishing varnish, epoxy paint, etc.. Solvent-based paint complete line consists of raw materials auto feeding system, metering system, dispersing and milling system, tinting system, filling system, auto control system, platform and color paste manufacturing part. The entire production line from charging, discharge to packing is totally automatic with high efficiency.

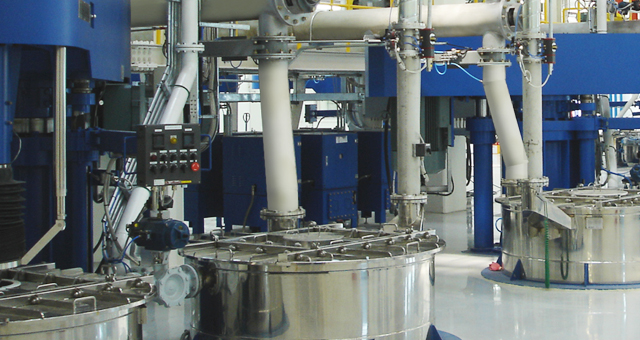

Resin is main raw materials for manufacturing plastics, in addition, it is also used for making paint, adhesion, insulating material, etc. . SIEHE provides design and manufacturing of complete production line from lab equipment to industry large-scale equipment. SIEHE industry resin complete production line consists of batching kettle(droplet add kettle), reactor, vertical distillation column, vertical condenser, horizontal condenser, water knockout drum, overflow tank, pipelines, attenuation harmony kettle, filling machine, etc main devices equipped with heating device(hot oil/steam boiler), cooling system(refrigerating machine/cooling tower), vacuum system, etc to make unsaturated polyester resins, phenolic resin, epoxy resin, alkyd resin, ABS resin, etc. It is also available for making emulsion.

SIEHE industry provides design and manufacturing of ink complete production line including: water-based ink, UV ink, inkjet, etc. Ink production line adopts raw materials automatic charging, metering system, dispersing and milling system(basket mill/horizontal beads mill/tri-roller mill), mixing system, cleaning system, automatic control system, automatic filling machine, etc advanced manufacturing method. The Completely automatic production process reduces workloads and avoids quality problems caused by human factors and herein, improves the products quality and efficiency to large extent.

SIEHE industry’s cosmetic complete equipment consists of homogenization main kettle(lifting cover, turnover kettle, co-axial mixing and emulsifying, dual-shaft mixer with scraper), water phase kettle, oil phase kettle, powder phase kettle(optional according to product, for example, toothpaste needs this kettle), vacuum system, electric heating or steam heating and temperature control system, PLC control system, etc. It is mainly used in manufacturing of high-level paste, medicinal soft ointment, emulsion, food emulsifying, etc.

SIEHE industry provides design and manufacturing of pesticide complete production line adopts raw materials automatic charging, metering system, dispersing &emulsifying and mixing system, milling system, cleaning system, automatic control system, automatic filling machine, etc advanced manufacturing method to realize automatic production. The Complete automatic production process reduces workloads and avoids quality problems caused by human factors and herein, improves the products quality and efficiency to large extent.

The Detergent Complete Production Line that SIEHE Industry design and manufacture is the professional equipment for production of daily chemical liquid product such as dish washing detergent, laundry detergent, softener,etc.. The production line consist of these parts: pre-mixing kettle, homogeneous emulsion kettle, weighing system, finished product mixing kettle, storage tank, heating system, cooling system, vacuum system, conveying system, filtration system, filling system, control system, etc; Automatic production process reduce work intensity of the operator and avoid the quality problem caused by human factors, so it greatly improve the product quality and production efficiency.

The Lubricant Complete Production Line consists of Pressure saponification reactor, mixing kettle, high pressure homogenizer, in-line homogenizer, hydraulic thi-roller machine, heating system, cooling system, vacuum degassing system, conveying system, filtering filling system, control system,etc.. It is special equipment for all kinds of biological oil, mineral oil and synthetic lubricants.

Stone paint is a kind of coating used for indoor and outdoor decoration with its effect like marble and granite in recent years. The features of simple and convenient construction, save time, safe, reliable, and adornment effect looks like marble, granite contributed to the rapid development of it. Really stone lacquer Complete Production Line consists of these parts: feeding system, stirring and mixing system(Horizontal Ribbon Mixer or Multi-functional Mixing Kettle), conveying system, dust removal system, measurement system, packaging system, control system, etc.

Putty is a kind of thick slurry coating, generally made of few binder, additives, made from a large number of fillers and pigments, which includes water base filler and oil base filler; It has many applications, such as batch of walls, interior walls, exterior walls, furniture, wood, metal etc. The different applications also determines the different production processes. The Siehe Industry for the optimal design of the production line can be according to the properties of puttymaterial features.

Siehe Industry design and produce printing and dyeing auxiliary production complete set for thickening agent, adhesive, cross-linking agent, emulsifier, dispersant and other professional equipment for printing and dyeing auxiliary. The production line consisted of mixing kettle, homogenizing emulsifier kettle (in-line high shear homogeneous emulsifier), weighing system, finished products mixing kettle, heating system, cooling system, vacuum system, transmission system, filtration system, filling system, control system, etc;

Adhesives consists of bonding material, curing agent, toughening agents, diluents, fillers, modifier composition etc., great variety and widely used in civil construction, paper and plants, automobiles, airplanes and ships, electronic and electrical, medical health and so on. Siehe industry has rich production experience in adhesives, and have a good command of powder and liquid feeding systems, conveyor systems, filling systems, automatization control systems. In addition, we have made an important breakthrough in the field of mixing

Battery slurry is divided into positive electrode slurry and negative electrode slurry. Positive electrode slurry consists of the binder, conductive agent, positive electrode materials etc.; Negative electrode slurry consists of the binder, graphite carbon powder and so on. For producing positive electrode slurry and negative electrode slurry, both need to mix, dissolve and disperse liquid-liquid materials and liquid-powder materials. During the process, temperature, viscosity and environment will be changed. SIEHE industry has a rich experience in producing battery slurry

Oil putty is a high polymer material, consists of the main ash (base ash) and the curing agent , the composition of the main ash is mainly unsaturated polyester resin and a filler, and the curing agent is generally initiator and a plasticizer, they play a role of initiating polymerization and enhancing performance. This nature of the material which can adhere to the surface of other material and prototyping rapidly is especially suitable for surface coatings applications, including automobiles, ships, factories, furniture, sheet metal etc.

Siehe Industry pay attention to the R&D of safety and healthy food additives, especially provides complete sets of equipment for food and food additive industry and project contracting services. Our products comply with GMP requirements. The mixing equipment is the center of food and food additive production complete sets and it will choose different mixer and its additional features according to different technical requirements;

Fine chemical industry is one of the most dynamic emerging field in chemical industry. Fine chemical products have widely use, and direct serve industries areas and high and new technology industry of national economy. Fine chemical rate (that is, the proportion of fine chemical industry output value of the total output value of chemical) has become an important indicator of developed chemical industry and chemical industry science and technology level of a country or region. The Siehe Industry has rich experience in equipment and production of fine chemical industry

Dry-mixed mortar refers to the aggregate by dry sieving process (such as quartz sand), inorganic cementitious materials (e.g. cement) and additives (such as polymer) according to a certain proportion after physical mixing to form a granular or powder, shipped to the site in bags or in bulk, then add water after mixing and use directly. The Siehe Industry has rich experience in equipment and production of fine chemical industry, and has provide equipment and construction services for many global well-known enterprises in the field of dry-mixed.

Refractories Complete Production Line, manufactured by SIEHE Industry, includes six parts: feeding system, conveying system, storage system, batching system, blending system and packing system. The production process is manual feeding, conveying each kind of ingredient into correspondent raw materials hopper through pneumatic conveying device. The quantities of main ingredient and other ingredients are controlled by batching system.

Gypsum powder, one of the five gel material, plays an important role in national economy. It is an important industrial raw materials widely used in many application areas such as building, construction materials, industry mold and art model, chemical industry, agriculture, food processing, medical and cosmetology, etc.. SIEHE Industry has accumulated rich experience of equipment application and production in gypsum powder field. And we have provided equipment and project construction service for many global gypsum powder production enterprises.

Powder metallurgy is the industry technology producing metal powder or use metal powder (or the mixture of metal powder and nonmetal powder) as raw material, after forming and sintering, to make out metal, composite materials and various types of products. At present, the powder metallurgy technology has been widely used in transportation, machinery, electronic, aerospace ,weapon, biological, new energy, information and nuclear industry areas, it becomes one of the most dynamic branches of the new material science. The manufacture of powder metallurgy materials contains the process of raw material powder preparation

Pigment, a group of materials can dye other subjects, are divided into soluble&insoluble dye and organic&inorganic dye. Dye, a group of materials can dye fiber and other materials, is divided into natural and man-made dye. SIEHE industry gathers rich experience in equipment application and manufacturing and has provides equipment and turnkey projects to lots of international pigment manufacturers, such as Mingsheng, Clariant , BASF and etc.

Pesticide, a group of materials can wipe out worms, germ, harmful animals or weed to keep and improve plant and crop healthy grow up. Chemical fertilizer is manufactured or mined and manually processed fertilizer, it is also called inorganic fertilizer. SIEHE industry gathers rich experience in equipment application and manufacturing and has provides equipment and turnkey projects to lots of international pesticide&fertilizer manufacturers. Mixing equipment, core device of pesticide&fertilizer complete production line, as well as additional function are chosen according to production process.

SIEHE industry gathers rich experience in equipment application and manufacturing and has provides equipment and turnkey projects to lots of international feed manufacturers. Mixing equipment, core device of feed complete production line, as well as additional function are chosen according to production process. Pre-mixing device includes: raw materials’ treatment system(unpacking, feeding, smashing, sieving, drying and etc.), raw materials’ transmission system, raw materials’ storage system, batching system, temporary storage system and etc. After-mixing devices includes: finished products transmission system, finished products temporary storage system, finished products before-packing treatment system(sieving, metal detecting and filtering and etc.)

Siehe Industry concerns the development and research of healthy pharmaceutical raw materials, provides complete equipment meeting GMP standard and contracts services. The pharmacy complete production line sets the mixing equipment as core, and choose different types of mixer with specific additional function according to different technics; the former part includes: raw material handling system(unpacking, feeding, crushing, sieving, drying, etc.), raw material conveying system, storage system, batching system and necessary intermediate storage system;

Siehe Industry has a wealth of experience in putty powder production, provides complete equipment and contracting services for enterprises home and abroad. The putty powder complete production line sets the mixing equipment as the core, and chooses different types of mixer with specific additional function according to different technics; the former part includes: raw material handling system(unpacking, feeding, crushing, sieving, etc.), raw material conveying system, storage system, batching system and necessary intermediate storage system; the latter part includes: finished products caching system, conveying system, temporary storage system, packing system, stacking system, etc.; the steel structure platform, dust collecting system and electric control system are also included.

ge and batching method of the liquid raw material is related to the production control, output efficiency and product quality degree. The improvement of batching automation level will make a great contribution to the industry production efficiency of the related fields. The Liquid Storage and Automatic Batching System that Siehe Industry design and manufacture is widely used in industries such as food, medicine, chemical, coating, ink, building material, etc.

The automatic level of storage and batching method of the powder raw material is related to the production control, output efficiency and product quality degree. The improvement of batching automation level will make a great contribution to the industry production efficiency of the related fields. The Powder Storage and Automatic Batching System that Siehe Industry design and manufacture is widely used in industries such as food, medicine, chemical, coating, ink, building material, etc.

With the prosperity of Chinese industry and increasing projects invested by Transnational Corporation in China, making the demand of project general contracting business also increased, however small and medium-scale projects are often faced with the difficulty of finding a general contracting services. Over the years, SIEHE industry focusing on design, workmanship experience accumulating and technical exchanges, maintaining a stable contact and cooperation with the world's leading engineering consultation, engineering design companies and domestic chemical institute.