Jetmixer Dispersing Emulsifier is the best option for some materials when simple mixer can not meet the production requirements and the dispersing function of the High-speed Dispersing Emulsifier is too strong. It produces powerful macro and micro mixing, which can fully disperses materials, no need for any other high shearing device to assist. Jetmixer Dispersing Emulsifier can generate ideal dispersing and mixing power to meet requirements of different production technology, easy to operate.

High-shear Dispersing Emulsifier narrows the particle size of liquid-liquid and liquid-solid materials through external mechanical force and distributes one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result. As a result, the materials form a stable emulsion state.High-shear dispersing emulsifiers a batch type machine.

Up-spray Dispersing Emulsifier consists of main shaft, the body, the baffle and other parts. Its specially designed rotor rotating at high speed sucks the materials at the bottom of the container to the stator and rotor area for shearing. And a adjustable baffle over the emulsifying work head stop the upward sprayed materials and spread around, finally go back to the bottom. This whole circulation repeats, which disperse and mix materials in a short time.

Inline High-shear Emulsifier is a continuous production type emulsifier with high efficiency. It processes materials in continuous production or circulation of fine materials. The motor drives the rotor to rotate at high speed.

The lab machine is a newly developed lab machine with multi-function and with high performance. It consists of driving system supporting system, control system, working components and auxiliary system. With the help of different working heads and optional components, one machine can carry out different working modes including Disperser, Basket Mill, Emulsifier, Mixer, Mixing Mill to provide more possibilities for lab application. High-quality components, high-precision processing, intelligent HMI, all make work easy and happy.

High-shear Emulsifier(Pneumatic Lifting) is a batch type machine designed for small volume in industrial production. Its working capacity is generally between 20-1000L. It narrows the particle size of Liquid-liquid and liquid-solid materials through external mechanical force and distribute one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result and obtain stable emulsion.

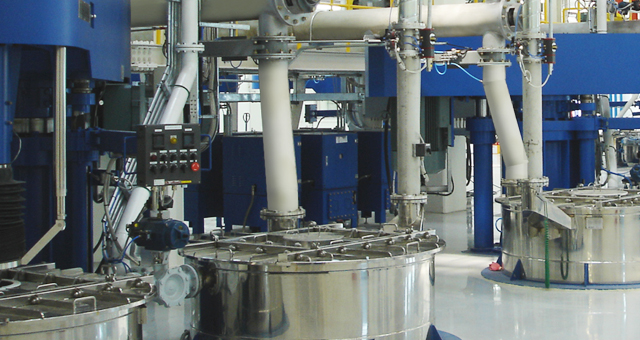

High-shear Emulsifier(Hydraulic Lifting) is a batch type machine designed for big volume in industrial production. Its working capacity is generally between 50-5000L. It narrows the particle size of Liquid-liquid and liquid-solid materials through external mechanical force and distributes one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result.

High-Shear Emulsifier (Vacuum type) is non-standard designed and manufactured according to customer's production processing. It is suitable for materials requiring for being emulsified and mixed under vacuum condition. Low-speed scraper is recommended to work together when emulsifying and mixing materials with high viscosity. It can work together with inline high shear emulsifier to carry out dispersing, emulsifying, homogenizing and mixing processes.

Vacuum emulsifying mixing unit is consisted of homogenizing emulsifying pot (lifting cover, tilting pot body), water pot, oil pot, scraper dual mixing, vacuum system, electric heating or steam heating temperature control system, electric control, etc. It is the equipment for top grade medicinal ointment, cream, emulsion.

Lab High-shear Emulsifier is a lab machine designed for small quantity experiment in lab. It narrows the particle size of Liquid-liquid and liquid-solid materials through external mechanical force and distributes one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result. As a result, the materials become stable emulsion. Several workheads are available. The smallest applicable container is standard tube with diameter 15mm.

Lab High-shear Homogenizer is a lab machine designed for small quantity experiment in lab. It narrows the particle size of Liquid-liquid and liquid-solid materials through external mechanical force and distributes one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result. As a result, the materials become stable emulsion. Several workheads are available. The smallest applicable container is standard tube with diameter 15mm.