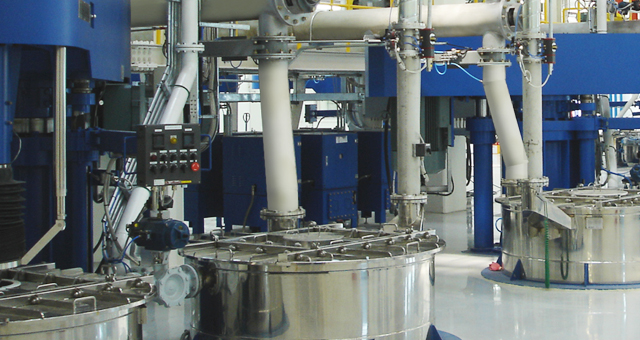

Horizontal drying mixer is a multi-function mixer combines mixing, reaction and drying, widely used in industries of food, chemical industries, building materials, lithium battery, etc., during the process of which the liquid needs to be added, and after mixing the liquid needs to be removed or the liquid content is too high so it needs to decrease. The machine is with heating jacket, which can heat the materials by hot water, hot oil, steam and other medium.

Horizontal ribbon mixer is a late-model mixing equipment with high efficiency, high uniformity, high loading coefficient but low energy cost, low pollution and low crush. The special design of double ribbon mix the materials into high uniformity in a few minutes. On the other hand, ribbon mixer shows a wide application from powder mixing , powder-liquid, to paste or materials in high specific gravity (such as putty, really stone paint, metal powder and other materials) and becomes one of the most popular single shaft horizontal mixing equipment.

Horizontal plough mixer is a Germany-technical late-model mixing equipment with high efficiency, high uniformity, high loading coefficient but low energy cost, low pollution and low crush. The agitator consists of multi-group of plough and fly-cutter which works together to mixing, smash, and dispersing materials. It is widely used in the mixing of powder=powder, powder-liquid and powder-particles, especially for the materials which may get aggregation during mixing. Liquid can be sprayed into powders. Vacuum system and drying system are also in option.

Horizontal non-gravity mixer is a Korean-technical late-model mixing equipment with high efficiency, high uniformity, high loading coefficient but low energy cost, low pollution and low crush. Agitators, designed in special angle, rotates in same but opposite direction and shows a nice mixing, smashing, dispersing results. It is widely used in powder-powder, powder-liquid, powder-particles mixing. It is also able to used for materials in different specific gravity and particles in a wide range of sizes.

This machine is suitable for powder-powder, powder-granule, powder-liquid mixing. Agitators, with a special design in different type (blade, plough, ribbon, etc.) are mounted inside the round, U-shape or O-shape working chamber, materials are fed into the inlet on one end, get mixed inside the chamber and discharge from the outlet on the other end. Normally the materials will stay in the mixer for around 30-120S to implement continuous feeding and discharging.

Horizontal drying mixer is a multi-function mixer combines mixing, reaction and drying, widely used in industries of food, chemical industries, building materials, lithium battery, etc., during the process of which the liquid needs to be added, and after mixing the liquid needs to be removed or the liquid content is too high so it needs to decrease. The machine is with heating jacket, which can heat the materials by hot water, hot oil, steam and other medium.

Nauta mixer is a late-model mixing equipment with high uniformity, low energy cost, low residue and low crush. There are two asymmetric spiral shafts, with their self-rotation and revolution, materials are lifted repeatedly to finally realize the purpose of well-mixed. It is one of the earliest developed products and till now, it is widely used to mix powder-powder and powder-liquid, especially for fine powder, fiber and slice materials.

Vertical conical ribbon mixer has advantages of good mixing performance, easy to discharge etc. Spray device, heating devices, lifting devices and drying devices are for option. Materials are lifted repeatedly, mist-spraying device uniformly sprays the liquid onto the solid materials, so that they will be well mixed. If this mixer is equipped with heating device then it will become an ideal drying machine.

V-shape mixer is mainly used for powder-powder mixing, especially for materials in small batch and has high uniformity requirement. The cylinder is rotatable. The mixing process is divided into stop & feeding, start & mixing, stop & discharging, etc. Vacuum feeding device can be equipped.

Double cone mixer is mainly used in powder-powder mixing, especially for materials in small batch and has high uniformity requirement. The equipment adopts W structure and cylinder is rotatable. The mixing process is divided into stop & feeding, start & mixing, stop & discharging, etc. Vacuum feeding device can be equipped.

3D mixer, moves in 3D space to eliminate gravity segregation, stratification and aggregation caused by centrifugal effect, can deal with and mix a group of materials in rapidly and homogeneous. Taking into all-round performance of all kinds of mixers, 3D mixer is still an ideal mixer in nowadays and it is widely used in powder and particle mixing of pharmacy, chemical industry, food, light industry, mechanical, mining, national defense and other research and development institution.

Screw conveyor according to the conveying form is divided into shaft screw conveyor and shaftless screw conveyor. According to the appearance, it is divided into U shape screw conveyor and tube type screw conveyor. Shaft screw conveyor is suitable for the non-sticky powder material and small particle material such as cement, fly ash, lime, food, etc.. Shaftless screw conveyor is suitable for conveying sticky and easy-winding materials such as sludge, biomass, litter, fibers, etc.

The machine is mainly applied for vertical elevating of power or granule materials. Multi buckets are installed on a circulation chain or belt. When working, the materials will be loaded into bucket from the bottom and then discharged when bucket moves to top. The buckets work continuously in circulation in a closed shell to realize continuous materials elevating. The machine is characterized in large elevating capacity, low energy consumption, low noise, good seal performance, no dust leakage, safe and reliable.

Belt conveyor is mainly used for horizontal or oblique conveying granules and not dusty materials. The materials are transported from materials charging port to materials discharging port in a cycled belt conveyor. It can be multi- charging points and multi-discharging points. It is with big transport capacity, low energy consumption, low noise, safe and reliable. The specially designed belt conveyor can also with multi discharging outlet. At same time, it also can be designed to be sealed belt to solve the dust flying problem of the belt conveyor.

Pipe Chain conveyor is a conveying machine for materials like powder, granules or small lumps in continuous way. It can be in horizontal transport, combination of inclined transport and vertical transport. Chain Conveyor is a new machine developed by Siehe Industry based on introduced new technology in foreign market. It solves the problem in powder mechanical delivery of long-distance heavy materials delivery. It is the first one exist in China market.

Vacuum feeder from Siehe Industry is newly developed product based on introduced counterparts in market at both home and abroad. It is the most advanced, ideal, improved vacuum feed for powder, granule and mixture of powder and granule in China. Vacuum feeder can deliver materials automatically to hopper of silo, packing machine, injection molding machine, pulverizer etc..

Vibrating Feeder is also known as vibrating feeding machine; it could put lumpish, granular materials into material accepting device uniformly, timely and continuously from silos during the production process, it could feed for crusher machinery continuously and evenly in gravel production line, and coarse screening the material, widely used in the crushing and screening combination equipment of the industries such as metallurgy, coal, mineral processing, building materials, chemicals, abrasives and so on.

Pneumatic conveying system is also named as airflow conveying system. It takes use of the airflow energy to deliver the granules along the airflow direction inside the closed pipeline. It is application of fluidization technology. It is divided into negative pressure conveying and positive pressure conveying.

The comminution mechanism of Air Jet Grinder decides its features of wide application range and high fineness of finished product. The typical materials include: super-hard diamond, silicon carbide, metal powder, etc.; high purity requirements: ceramic pigment, medicine, biochemical, etc; low temperature requirements: medical, PVC. The machine can be inert gas protection equipment by changing parts of ordinary air to inert gas such as nitrogen and carbon dioxide gas

All-round grinder consists of main grinder, ultrafine powder collection device and electric cabinet. It is characterized in stable technical performance, low noise, electricity saving, high productivity, nice appearance, stable running, compact structure and space-saving etc.. Strictly accordance with the GMP standard design, can ensure the cleanliness of crushing material, no dust float in the sky in the process of production, and can improve the utilization rate of material. It is widely used industry such as medicine, food and chemical.

Micro Grinder consists of main driving device, ultrafine powder collection device, powder delivery pipeline and electric cabinet. The air classification device is installed in the main driving machine, enable to adjust the granularity of the finished products arbitrarily and to make material’s temperature increase slow during grinding, and also to avoid materials over-crushing. It is characterized in stable technical performance, low noise, electricity saving, high productivity and especially suitable for grinding heat sensitive materials such as sugar, plastic powder and traditional Chinese medicine etc.

Large storage bin is used for storing powder materials. It is normally designed in vertical-type and stands inside or outside door with platform or support legs. Warehouse roof dust, oscillator, level gage and etc are in option to equip with that. In addition, bins can be made of carbon manganese steel, stainless steel, zirconium, nickel based(Ahab, Monel and Inconel) alloys and other composite, and stainless steel bin and carbon manganese steel bin are SIEHE’S star products. Large storage bins are widely used in pharmacy, food, chemical industry, paint, ink, building mortar and other powder industries.

Intermediate bin is a temporary storage container widely used in chemical industry, rubber, pesticide, bye, pharmacy, food and etc industries. It is important to some process need a intermediate link(temporarily store or improve efficiency), for example, in air transmission it is needed to relief pressure, an intermediate storage bin is needed before mixing and a finished bin is needed before packing. Intermediate bin is usually made of carbon manganese steel, stainless steel, zirconium, nickel based(Ahab, Monel and Inconel) alloys and other composite, and stainless steel bin and carbon manganese steel bin are SIEHE’S star products.

Weighing bin is a weighing container widely used in chemical industry, rubber, pesticide, bye, pharmacy and food etc industries. It is usually used in powder automation production line. There is loading cells mounted on bins which are equipped with batching meter and calculate the weight in add method. Intermediate bin is between raw materials storage bins(each for every raw material) and mixing equipment or packer to realize a pipelining operation .

SIEHE Industry provides various auxiliary devices for powder bins, including: level gage, pneumatic valve, rotation valve, broken device, warehouse proof dust collector, feeding station and etc to meet requirements of modern production.

Small bag Feeding Stations is commonly used for unpacking and discharging for bags (25kg or 50kg) filled with powder or granule materials. The unpacking and discharging work is done through manual bag open, automatic dumping and let the materials fall down by gravity to the storage hopper. The dust generated during operation is collected by the build-in dust collection to ensure clear working environment for operators.

The Ton-bag discharging and feeding station is used for unpacking and discharging powder and granules in T-bag. This equipment consists of the rack, lifting device, diaphragm valve, temporary storage silo and so on; Two types: Use hoist and forklift according to production technology and equipment size. Dual track is optional for occasion of two electric hoist installation to increase the bag unpacking efficiency. The machine can be carbon steel or stainless steel. The whole machine is with good airtightness, easy to operate, which improve the working environment and also the production efficiency significantly.

Discharging and Feeding Station for both small bag and ton bag is a new developed discharging and feeding system for not only ton bags but also small bags base on the ton bag discharging and feeding station, combined feeding to realize main material and auxiliary material discharged and fed at the same time. Dust removal and sieving function are in options. The machine can be carbon steel or stainless steel. The whole machine is with good airtightness, easy to operate, which improve the working environment and also the production efficiency significantly.

Small-bag Automatic Discharging Station is used for unpacking and discharging powder and granule materials in small bag. Automatically provide bags through belt conveyor, cutting device to break the bags automatically, vibrator to separate the bag and materials automatically, discharging materials etc.. Then the materials fall down to the storage hopper through gravity.

Bag-type dust collector is a dry dust filtering device. It is suitable to catch tiny, dry and not-fiber powder. The filter bag is made of woven or non-woven cloth, taking use of the fabric filtering function. When gas with a contain dust content goes in to bags, big particles fall to dust hopper as the gravity, and small ones stopped at the filtering cloth as its filtration of fabric, therefore, gas is cleaned.

Cartridge type dust collector is not only has the same advantages as the bag type dust collector of good soot cleaning effect, high efficiency and low emission, but also has the features of stable, low energy cost and small area, suitable to deal with the gas and ash-laden gas with large air quantity. It is widely used overseas, and now, it is also accepted by many Chinese companies.

Roof dust collector is a kind of de-dusting equipment used in bins. It can be divided into bag-type and cartridge type. Roof dust collector is nowadays widely used in powder pneumatic conveying process and the filtration area are designed according to capacity, proportion of gas and powder, air pressure, air speed and etc parameters.

Airflow sieve is a kind of high accuracy sieving equipment for micro powder with sieve, which is widely used in chemical, pharmaceutical, food, paper making, metallurgy, building materials, rubber, mechanical and other industries. It can sieving continuously for powders with fineness range within 80-500mesh.

Rotary sieve is a sieving machine with high precision for fine powder. It is characterized in low noise and high efficiency, exchanging sieve only takes 3-5minutes. Completely closed structure and suitable for sieving granule, powder, and sticky liquid. Having a vertical motor as the vibration source, and the motor is with bias hammer mounted on both the top and bottom of the motor to make the rotation motor to move in there directions: horizontal, vertical and inclined direction.

Straight discharge screen is based on single/double horizontal vibration motor as vibration source. Vibration motor is on one side of the body. The materials will be under the action of the vibration source after they go into the machine and do elliptical orbit movement. After materials going to the sieve, the vibration force will repeatedly and continuously peel, break up and reorganize the materials to have them go through the sieve rapidly.

Valve bag semi-auto packing machine uses signals sent by weighing sensors to control feeding speed to realize auto packing. It is mainly used to pack 10KG-50KG powder valve bag. It is divided into screw valve bag packer and air-sweeping valve bag packer according to its feeding method. Thereinto, screw valve bag packer can be applied in materials in wide range of specific gravity as well as the materials with bad fluidity with high packing accuracy, slow packing speed and less dust; on the other hand, air-sweeping valve bag packer is normally used to pack common powder materials with low packing accuracy requirement, more dust so it should be equipped with dust collectors. Overall, valve bag packer can be widely used in various of industries to pack all kinds of powder, fines or materials in particles

Valve-bag auto packing machine is an newly-developed intelligent packer based on valve bag semi-auto packing machine, consists of auto delivering bag, absorb, bagging, constant feeding, delivering devices, etc. . Constant feeding device uses signals sent by weighing sensors to control feeding speed to realize auto packing. It is mainly used to pack 10KG-50KG powder valve bag, divided into screw valve bag packer and air-blowing valve bag packer according to feeding method.

Top open Bag Semi-auto Packing Machine uses signals sent by weighing sensors to control feeding speed to realize auto packing. It is mainly suitable for top open bag (10kg-50kg).. Different types feeding ways are optional including two screw feeding, single screw feeding, big/small valve feeding, vibration feeding etc.. The machine is with wide application range suitable for packing different powders, super fine powders or granules in different industries.

Top open Bag Auto Packing Machine is an newly-developed intelligent packing machine based on Top open Bag Semi-auto Packing Machine. It consists of auto delivering bag, sucking bag, bagging, quantitative packing, shaping and sewing and bag delivery etc. Quantitative packing adopt weight type. It uses signals sent by weighing sensor to control feeding speed to realize auto packing. It is mainly suitable for top open bag (10kg-50kg). Different types feeding ways are optional including two screw feeding, single screw feeding, big/small valve feeding, vibration feeding etc.. The machine is with wide application range suitable for packing different powders, super fine powders or granules in different industries.

Automatic screw packing machine is mainly used to pack fine powders easy to be dusty and with requirement of high precision. The machine is made of stainless steel, complying with requirements of food grade and chemical corrosion resistance. It integrates mechanical, electrical, optical, instrument into one, SCM control, with functions of auto weighing, auto filling, auto correct weighing error, auto track and correct the error due to different materials level and different specific gravity.

Small bag Auto Packing Machine a developed new generation smart packing machine based on Vertical Screw Packing Machine. One machine do all works: Auto bag-making, weighing, inserting nitrogen, coding, cutting bags. Its electric control system adopts advanced programmable controller and LCD touch screen display which are easy to operate and have good man-machine interface. With characteristics of fast packing, high accuracy and strong anti-interference ability, it is widely used in chemical, salt, grain and other granular powder industries.

Ton Bag Packing Machine is weighing type. It uses signals sent by weighing sensors to control feeding speed to realize auto packing. It is mainly suitable for packing powders in ton bag. Different feeding methods are optional for ton bag packing including two screw feeding, single screw feeding, small and big valve feeding, vibration feeding etc.. The equipment is a multi-functional packing machine integrating electronic weighing, auto bag releasing, dust collecting. It is with high automization, high packing accuracy, adjustable packing speed and superior structure.