The lab machine is a newly developed lab machine with multi-function and with high performance. It consists of driving system supporting system, control system, working components and auxiliary system. With the help of different working heads and optional components, one machine can carry out different working modes including Disperser, Basket Mill, Emulsifier, Mixer, Mixing Mill to provide more possibilities for lab application. High-quality components, high-precision processing, intelligent HMI, all make work easy and happy.

Lab Butterfly Type Dispersing Mixer is a newly developed lab machine with dispersing and mixing (with scraper) function. It is good for the materials with mid-and-high viscosity and thixotropy property. It can go on dispersing and mixing process at the same and is with good adaptability. Besides, customized design is provided based on the property and technology process of processed material.

Lab Scraper Type Disperser is a newly developed lab machine with dispersing and scraper function. During dispersing process, scraper rotates along the tank wall and generates a radial mixing flow. In addition, the PTFE scraper can scrape the materials on the tank off efficiently. It is good for the materials with mid-and-high viscosity and thixotropy property. The finished products can be discharged completely and the tank is easy to clean.

Dual-shaft High-speed Disperser (Hydraulic Lifting) is a machine with dispersing and mixing (scraper) function developed based on single shaft ones. It is good for the materials with mid-and-high viscosity and thixotropy property. Dispersing and mixing of materials can work at same time, which makes it more adaptable. It also can be customized based on the materials property and production technology.

Platform type High-speed Disperser (Hydraulic Lifting) is for dispersing and mixing materials with mass production . With inverter various speed control, can be used continuously for a long time, stable operation and low noise. The dispersing disc is easy to be disassembled. Dispersing discs with different sizes and different design can be designed according to the production technology. The dispersing set is fixed on the kettle and can move up and down within certain range. It is an ideal machine for dispersing and mixing. It is also can be customized to be mounted on kettle type.

High-speed Disperser (Hydraulic Lifting) has dispersing and mixing function, which used for mass production; Equipment with inverter has stepless speed, can operate for a long time. It has stable running and low noise; Mixing disc is easy to be replaced, and can change different forms of dispersing discs according to production technology; Lifting structure adopts hydraulic cylinder as actuator, stable lifting, integrated hydraulic station, environmental and without leakage. It is an ideal grinding machine for materials with many varieties and many colors.

High-speed Disperser with lifting cover is a functional product developed based on the standard Hydraulic High-speed Disperser. Its unique lifting cover structure can prevent material splash and reduce the solvent volatilization effectively.

Vacuum High-speed Disperser is a functional machine developed based on the standard High-speed Disperser. A closed lid, with spring seal ring mounted in a milling groove of the cover flange, is completely closed with tank and ensures no air leakage under vacuum operation surroundings. Vacuum pumps are option whose limited vacuum degree can be -0.0998mpa(20mbar). It shows excellent performance during special dispersing condition such as vacuum defoaming, vacuum charging, inert gases protection and etc..

Wall Mounted High-speed Disperser is the disperser mounted to the wall, widely used in Euro market. It saves producing room significantly and especially suitable for small-batch production of products with many varieties.

Coaxial High-speed Disperser (Hydraulic Lifting) is a kind of product with function of dispersing, scraping, and vacuumizing. During dispersing process, scraper can rotate along the tank wall and generates a radial mixing flow. In addition, the PTEF scraper can scrape the materials on the tank off efficiently.

High-speed Disperser with Multi-tanks (Hydraulic Lifting) is for dispersing and mixing materials with mass production; With inverter various speed control, can be used continuously for a long time, stable operation and low noise.

High-speed Disperser (Pneumatic Lifting) is with function of both dispersing and mixing. It is a mid batch machine widely used for small batch production in factories, scientific research institutions, universities etc..It is with inverter to realize various speed control, can run for a long time, low noise and stable option. The dispersing disc can be easily disassembled.

The lab machine is a newly developed lab machine with multi-function and with high performance. It consists of driving system supporting system, control system, working components and auxiliary system. With the help of different working heads and optional components, one machine can carry out different working modes including Disperser, Basket Mill, Emulsifier, Mixer, Mixing Mill to provide more possibilities for lab application. High-quality components, high-precision processing, intelligent HMI, all make work easy and happy.

Basket Mill (Hydraulic Lifting) integrates dispersing and grinding into one machine, suitable for grinding liquid materials with mid and low viscosity. It is a batch type industrial production machine with suitable and reasonable basket structure, easy to clean and to change colors / varieties.

Closed type Basket Mill(Hydraulic Lifting) is a functional machine developed based on the standard Basket Mill(Hydraulic Lifting); The equipment has airtight vacuum cover matching with the tank exactly, the vacuum cover flange is with slot and elastic sealing ring which is anti-corrosive to ensure there is no leakage when it is under closed and vacuum condition. It can also come with vacuum pump or set of vacuum pump team, the highest vacuum degree can reach -0.098mpa(20mbar). It is applicable for dispersing and grinding under special working condition such as vacuum degassing, inert gas protection etc.

Basket Mill (Pneumatic Lifting) integrates dispersing and grinding into one machine, suitable for grinding liquid materials with mid and low viscosity. It is a small batch production widely used in Institutions, research institutions, universities etc..

The machine has altered traditional production processing by integrating dispersing and milling two processes into one, which reduces production process significantly. It increase production efficiency and reduce waste. Compared to other lab equipment, mid-batch basket mill has high efficiency and high finesse, and it is easy to clean, and fit for grinding different material.

Basket Mill(Mounted on Kettle) is fixed on various containers, widely applied in complete production line. After grinding, the raw material will be transported to the next procedure through pipeline, which makes it easy to become automatic, programmable, and digital operation. It is the ideal grinding equipment in the automatic production line.

All-round Horizontal Beads Mill is a Nano Grade liquid grinding machine for closed continuous production. Comparing with traditional grinding equipment, it uses Yttrium stabilized zirconium beads with higher specific gravity and higher hardness as grinding medium.

All-round Horizontal Beads Mill is a Nano Grade liquid grinding machine for closed continuous production. Comparing with traditional grinding equipment, it uses Yttrium stabilized zirconium beads with higher specific gravity and higher hardness as grinding medium. And it shows higher grinding efficiency(2 to 3 times higher), better final fineness(nano grade), wider application(Available for middle and high viscous materials) and better wear resistance. Various of specifications are in option, easy operation and high reliability.

Lab Horizontal Beads Mill -A is a Nano Grade liquid grinding machine with high performance for labs of collages, research institutes and factories. It is application for liquid materials with low and mid viscosity. The rotation speed is with digital display (0-2880rpm), various speed control.

Mid-batch horizontal beads mill is a Nano Grade liquid grinding machine for labs of collages and research institutes. Metering pump can be used to adjust the flow to gte the best grinding results. The device is controlled by PLC, all the materials temperature, materials pressure and electric current can be supervised and protected. Faults can be checked, therefore, it is easy to be maintenance. Grinding medium, tiny pure zirconia beads, are with high efficiency, good grinding fineness, wildly use and strong anti-wear.

Lab Horizontal Beads Mill-C is a Nano Grade liquid grinding machine with high performance for labs of collages, research institutes and factories. It is application for liquid materials with low and mid viscosity.

Traditional Tri-roller mill is suitable for grinding and dispersing ointment or high viscosity slurry with comparatively high requirement of fineness. It achieves required grinding effect at different speeds by the friction and crashing and manual adjustment of the interval among the three horizontal rollers rotating.

Tri-roller mill is suitable for grinding and dispersing ointment or high viscosity slurry with comparatively high requirement of fineness. It achieves required grinding effect by the friction and crashing among the three tilt rollers rotating at different speeds.

Jetmixer Dispersing Emulsifier is the best option for some materials when simple mixer can not meet the production requirements and the dispersing function of the High-speed Dispersing Emulsifier is too strong. It produces powerful macro and micro mixing, which can fully disperses materials, no need for any other high shearing device to assist. Jetmixer Dispersing Emulsifier can generate ideal dispersing and mixing power to meet requirements of different production technology, easy to operate.

High-shear Dispersing Emulsifier narrows the particle size of liquid-liquid and liquid-solid materials through external mechanical force and distributes one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result. As a result, the materials form a stable emulsion state.High-shear dispersing emulsifiers a batch type machine.

Up-spray Dispersing Emulsifier consists of main shaft, the body, the baffle and other parts. Its specially designed rotor rotating at high speed sucks the materials at the bottom of the container to the stator and rotor area for shearing. And a adjustable baffle over the emulsifying work head stop the upward sprayed materials and spread around, finally go back to the bottom. This whole circulation repeats, which disperse and mix materials in a short time.

Inline High-shear Emulsifier is a continuous production type emulsifier with high efficiency. It processes materials in continuous production or circulation of fine materials. The motor drives the rotor to rotate at high speed.

The lab machine is a newly developed lab machine with multi-function and with high performance. It consists of driving system supporting system, control system, working components and auxiliary system. With the help of different working heads and optional components, one machine can carry out different working modes including Disperser, Basket Mill, Emulsifier, Mixer, Mixing Mill to provide more possibilities for lab application. High-quality components, high-precision processing, intelligent HMI, all make work easy and happy.

High-shear Emulsifier(Pneumatic Lifting) is a batch type machine designed for small volume in industrial production. Its working capacity is generally between 20-1000L. It narrows the particle size of Liquid-liquid and liquid-solid materials through external mechanical force and distribute one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result and obtain stable emulsion.

High-shear Emulsifier(Hydraulic Lifting) is a batch type machine designed for big volume in industrial production. Its working capacity is generally between 50-5000L. It narrows the particle size of Liquid-liquid and liquid-solid materials through external mechanical force and distributes one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result.

High-Shear Emulsifier (Vacuum type) is non-standard designed and manufactured according to customer's production processing. It is suitable for materials requiring for being emulsified and mixed under vacuum condition. Low-speed scraper is recommended to work together when emulsifying and mixing materials with high viscosity. It can work together with inline high shear emulsifier to carry out dispersing, emulsifying, homogenizing and mixing processes.

Vacuum emulsifying mixing unit is consisted of homogenizing emulsifying pot (lifting cover, tilting pot body), water pot, oil pot, scraper dual mixing, vacuum system, electric heating or steam heating temperature control system, electric control, etc. It is the equipment for top grade medicinal ointment, cream, emulsion.

Lab High-shear Emulsifier is a lab machine designed for small quantity experiment in lab. It narrows the particle size of Liquid-liquid and liquid-solid materials through external mechanical force and distributes one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result. As a result, the materials become stable emulsion. Several workheads are available. The smallest applicable container is standard tube with diameter 15mm.

Lab High-shear Homogenizer is a lab machine designed for small quantity experiment in lab. It narrows the particle size of Liquid-liquid and liquid-solid materials through external mechanical force and distributes one phase materials into another phase or many other phases evenly to realize good homogenizing, dispersing and emulsifying result. As a result, the materials become stable emulsion. Several workheads are available. The smallest applicable container is standard tube with diameter 15mm.

Hydraulic Lifting Mixer generally refers to single shaft mixer; it is used for mid to mass production with functions of stirring and mixing. It can be equipped with frequency converter various speed control or constant speed operating; It can be used for long-time operation, with stable operation and low noise. The impeller is convenient to disassemble and different forms of impeller can be changed according to the processing property.

Dual Shaft Mixer(Hydraulic Lifting) is a product with dispersing, emulsifying, stirring functions developed on the basis of Single Shaft Hydraulic Lifting mixer. It is divided into co-axial dual shaft mixer and independent dual shaft mixer according to whether the shafts are designed in co-axial or not.

三轴多功能液压升降搅拌机是在双轴液压升降搅拌机基础上开发的一款具备分散/乳化/搅拌+搅拌功能的产品;该产品对中高粘度及触变性物料具有很好的适应性,多种搅拌方式可选,常规的如锚式、蝶式、框式等,分散/乳化与搅拌可同时进行,适应性强,并可根据客户的物料的特性和生产工艺要求进行非标定制。

Vacuum Multi-functional Mixer is a functional product SIEHE company developed on the basis of standard multi-functional mixer. The machine has equipped with matched closed vacuum cover, flange slotting and elastic sealing ring to the tank, to ensure no leakage under the closed vacuum condition.

Mixer Mounted on kettle is functioning in stirring and mixing of liquid-liquid and liquid-powder for the mass production product, and it can be supplemented by dispersing, emulsifying, heating and cooling functions to meet the needs of different production process. The machine can be used continuously for long period, stable operation and low noise, easy operation, strong adaptation; it is ideal equipment for multi-function as mixing and dispersing.

Lab Mixer is small mixing equipment SIEHE developed to meet the requirement of institutions and scientific research unit. With digital rotation speed display (0~1500rpm),various speed control, stable operation and low noise; Two form of mixing agitators, easy disassemble, simple lifting structure operation. It is ideal lab equipment for trial.

Pneumatic Lifting Mixer has the feature of simple lifting, good mixing effect, beautiful structure, beneficial price, and high performance. It is used for small batch production of factories, scientific research institutions and colleges. The equipment is equipment with inverter various speed control, can be used continuously for a long period of time, stable operation and low noise; Various optional mixing paddle, easy disassemble and change; The lifting structure use cylinder as actuator, environmental protection and no pollution, it is an ideal equipment for small batch production.

Various kinds of agitator combination optional for providing mixing device with more optimized, more reliable and lower maintenance cost and running cost. The machine is suitable for mixing solid-solid, liquid-liquid (dissolving, dispersing), solid-liquid, air-liquid or combination of materials in different state.

Reactor is a kind of atmospheric pressure or pressure vessel that is applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries, and used to complete the process of vulcanization, nitration,hydrogenation, alkylation, polymerization, condensation, also called polymerization reaction kettle, reactor, decomposition kettle, etc.

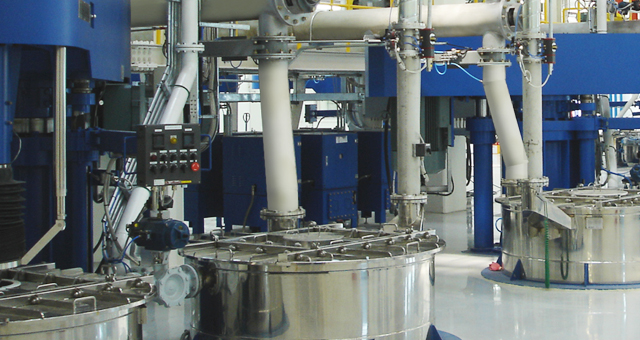

Mixing kettle, which is used for liquid-liquid or powder-liquid blending and mixing, is a type of large-scale production equipment and has the functions of dispersing, emulsifying, heating and cooling, to fulfill different production process requirement; It can be stably running for long time, has the advantages of small noise, simple operation and strong adaptability, is the ideal multi-functional equipment for mixing and dispersing.

Atmospheric pressure vessel, is a kind of vessel shares same pressure as atmosphere, applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries, and used to complete the process of storage, temporary storage or non-pressure mixing. This type of machine is usually equipped with breathing valve or vent.

Pressure vessel, is a kind of vessel that carries certain pressure, applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries, and used to complete the process of storage, temporary storage or mixing. This type of machine is special technical equipment.

Vertical storage tank, is a kind of storage container applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries. Vertical storage tank includes atmospheric pressure storage tank and pressure storage tank. The equipment material usually adopts carbon manganese steel, stainless steel, zirconium, nickel based (Harrington, Meng Naier, Kang Nie) alloy and other composite materials. Siehe Industry mainly produces the stainless steel or carbon manganese steel model.

Horizontal storage tank, is a kind of storage container applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries. Horizontal storage tank includes atmospheric pressure storage tank and pressure storage tank. The equipment material usually adopts carbon manganese steel, stainless steel, zirconium, nickel based (Harrington, Meng Naier, Kang Nie) alloy and other composite materials. Siehe Industry mainly produces the stainless steel or carbon manganese steel model.

Intermediate tank, is a kind of temporary storage container applicable for petroleum, chemical, rubber, pesticide, dyestuff, medicine, food and other industries. Intermediate tank can be also used for liquid and powder dispatching process, such as layering, solvents and water separation, purification, etc. The equipment material usually adopts carbon manganese steel, stainless steel, zirconium, nickel based (Harrington, Meng Naier, Kang Nie) alloy and other composite materials. Siehe Industry mainly produces the stainless steel or carbon manganese steel model.

Sanitary vessel, includes storage vessel, tank and mixing tank, etc.,is mainly applicable for industries like: biological, pharmaceutical, food, beer & beverage, dairy product, fine chemicals, cosmetics, etc., entirely designed and manufactured in accordance with SMP standard. The part contacting materials is mirror polished to Ra≤0.28um, and surface is polished, mirror polished, sandblasting or matte treated. Level meter port, air respirator, thermometer, CIP cleaning port, SIP sterilization port, sight glass(integrated with a lamp), inlet and outlet and manhole etc.are optional.

Movable tank, referred to as tank, is mainly used for small scale production mixing or storing. The tank adopts high-quality stainless steel, argon-arc welding whose seam has been nicely treated; mirror polished inside and outside, easy to clean; also, the tank bottom is with inclination angle ensures clean discharging and no residue。

In the actual production, the factors such as materials feature, production process, operation requirement and volume etc. varies a lot, so besides the normal standard vessels, Siehe also do non-standard vessels’ customizing. The customized vessels can be combined with dispersing, grinding, emulsifying, heating, cooling and vacuum function, to fulfill the needs of different production process.

Bag-type Filtrating system is a new type filtrating system. Liquid flows into filtering bag inside supported by metal net basket from inlet, and comes out from the outlet of filtering bag. Impurities are left on the bags and the machine can be continually used by replacing bags. The bag-type filter is mainly used of coarse filtration. A pressure gauge is equipped for reminding the bag replacement when the pressure is too high.

Cartridge Type Filter is a filtration device with high precision. It mainly consists of cartridge, shell and fixing device. Liquid enters from the filter inlet, the impurities will be stopped at the surface and inner layer of the cartridge when they go through the cartridge. The clean liquid flow out from the outlet. Cartridge Type Filter from is mainly used for filtrating material with low-and-mid viscosity. It is applicable for different filtration ways such as finish cartridge filtration, fine filtration and millipore filtration to remove the tiny impurities and bacteria out of the finished products.

Vibration Sieve from Siehe Industry is mainly used for separating big particles from small particles, solid from liquid for both powder and liquid materials. It is widely used in industries such as paint, ink, pigment, adhesive, resin, polymer and etc.

Scraper type Self-cleaning filter is able to auto remove the particles accumulated on filtration surface through high efficient mechanical scraping type. And auto discharge the liquid with high impurity concentration collected inside the chamber through the time difference and pressure difference controlled by PLC. The discharged liquid can be recycled or disposed. Rotation scraper can be divided into inside scraping and outside scraping.

Disc type Self-cleaning Filter is able to auto remove the particles accumulated on filtration surface through high efficient mechanical scraping type. And auto discharge the liquid with high impurity concentration collected inside the chamber through the time difference and pressure difference controlled by PLC. The discharged liquid can be recycled or disposed.

Filter cart consists of a stainless steel bag type filter, a pneumatic diaphragm pump, air filter and oil lubricator, single air control valve, all the components are on the cart. It can be removed to any place of the production line. Bag-type Filtrating system is a new type filtrating system. Liquid flows into filtering bag inside supported by metal net basket from inlet, and comes out from the outlet of filtering bag. Impurities are left on the bags and the machine can be continually used by replacing bags. The bag-type filter is mainly used of coarse filtration. A pressure gauge is equipped for reminding the bag replacement when the pressure is too high.

Filter cart consists of a stainless steel bag type filter, a pneumatic diaphragm pump, air filter and oil lubricator, single air control valve, all the components are on the cart. It can be removed to any place of the production line. There are multi-method of filter group in option, normally, it is a group consists of a bag-type filter and a cartridge filter. Delivery pump sucks the raw materials from finished vessel to the filter group, go through the bag filter for coarse filtration first and then go toe the cartridge filter for fine filtration to obtain required finished products.

Semi-automatic Filling Machine(Weighing Type )adopts gravimetric method to measure, by weighing sensor output signal to control the charging valve opening, so as to realize the purpose of automatic filling. By equipped with a pump in the front end of the feeding port, or pressuring the material tanks to sent material from tank to the filling machine. The filter device can be added before filling to guarantee the quality of products.

Semi-automatic Filling Machine (Volume Type) adopts volumetric method to measure, through the way adjusting the plunger volume to realize the control of filling quantity. It is equipped with a pump in the front end of the feeding port, or pressuring the material tanks to send material from tank to the filling machine.

High Viscosity Semi-automatic Filling Machine adopts gravimetric method to measure, by screw extruder or high viscosity convey pump (such as screw pump, rotor pump) for feeding, conveying device with the function of frequency speed control can realize quick or slow feeding. Weighing sensor output signal control screw and the discharge of the pump (fast, slow, or stop feeding) to achieve automatic filling.

Big Drum Semi-automatic Filling Machine adopts gravimetric method to measure ,by weighing sensor output signal to control the charging valve opening, so as to realize the purpose of automatic filling. By equipped with a pump in the front end of the feeding port,or pressuring the material tanks to sent material from tank to the filling machine. The filter device can be added before filling to guarantee the quality of products.

Multi-heads Linear Automatic Liquid Filling Machine(Volume type) has the advantages of linear filling, which can apply to a variety of specifications of the bottles, convenient adjustment, free of maintenance and design, measurement methods using piston volume filling, continuous work, lasting stability, can match 2 to 12 filling head, and with the bottle convey ,position structure ,positioning ,screw cap cover device, whole machine PLC control, with detection device, no bottle no filling, no set or screw cap, filling with high efficiency, high filling precision, safety, and intelligent advantages.

Automatic Liquid Filling Machine (Volume Type) consists of the following parts: automatic arrangement of dividing barrel and lift barrel system, double head volume type filling system, convey system, automatic lift and gland cover system, automatic code/labeling system, the finished product output system, packaging platform, control system etc..

Automatic Liqui: filling Machine(Weighing Type) consists of the following parts:barrel lifting system, filling system, weighing system, block system, pallet supply system, pile tally system, electric appliance control, pneumatic control, vacuum system, rack, etc.. Under the electrical control, the machine finished the working of automatic bucket,quantitative filling,cover,detect,pallet, pre-stacking,stow and barrel pushed and automatic output. Automatic barrel lifting system: Filling machine is all automatic production from the barrel access part, only need to placed the same specifications and types of barrels neatly in the designated position,

Automatic Filling Machine (Big Drum) consists of automatic input and output track system, material automatic convey system, filter system, automatic canned metering system,the air and ground operation path, control system. Implements the process of send into barrels automatically- automatic peeling - automatic seek the barrel mouth -automatic fall down - fast canned - slow accurate canned- automatically rise after canned - seek barrels mouth repeatedly - four barrel canned end - automatic send barrels out - new bucket automatically to the filling position.

Automatic Filling and Sealing Machine control part adopts the most advanced intelligent man-machine interface control, large screen touch screen display/control panel operation, including temperature setting, motor speed, production speed and so on, directly display on the screen, and can be directly control and adjust on the screen.

Small Batch Paste&Filling Machine(Volume Type )adopt volumetric method to measure,through the way adjust the plunger volume to realize the control of filling quantity.The reciprocating movement of the piston achieves filling rapidly.The equipment has advantages of high filling efficiency and easy maintenance.

The progress of modern science and technology make all walks of life are gradually entering into the automatic intelligent generation. SIEHE Industry has professional R&D team, who has continuous innovation, and has been developing sorts of new product keeping pace with the times. We have formed a series of product: Semi/Automatic Filling Machine (Volume Type), Semi/Automatic Filling Machine (Weighing Type), Semi/Automatic Filling Machine (Big Drum)